In the event of deforestation, the natural capacity of the ground to hold the runoff rainwater has diminished. The precious rainwater keeps flowing with greater speed, causing flood-like situations. It has also resulted in non-recharging of the used groundwater. To cope up with the situation, numerous water recharge methods have been deployed, based on the geographical need of the place. Construction of the recharge pits is one such method.

Our country is rich in resources. The prevalence of different meteorological and climatic conditions supports various species of plants and animal life including human beings. Being the smartest among animal kingdom, we humans have taken out the ways of using the resources to its maximum. And since we are getting very large in numbers, our efforts have led to the overuse or rather exploitation of natural resources. Groundwater is one natural resource which is being taken for granted.

Groundwater is the water that percolates into the land. The replenishing sources of the groundwater are the flowing river streams or lakes or the rainwater. The quality of sand and the vegetation or trees in the area controls the amount of water that can be absorbed by the ground, replenishing the lost groundwater aquifers. With the loss of both- the quality of sand and the vegetation, the land is struggling to get enough water for percolation. The extraction of this low quantity groundwater through handpumps and borewells have worsened the condition. This calls for the measure called artificial groundwater recharge.

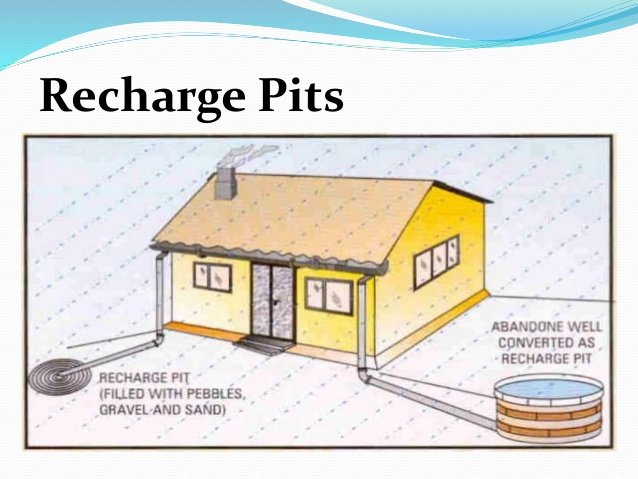

Amongst many methods, use of recharge pits for artificially recharging dewatered aquifers, is popular.

Recharge Pit- Selection of the Site

Recharge pits are closed well like structure, which is covered by filling the stones, after digging the land to make a pit.

The pit, if aimed for recharging the borewell, must be constructed near the borewell, as close as possible. In another case, the selection of the site becomes the most important step in the construction of recharge pit.

The site is well suited if:

- It has a sufficiently clean and large catchment area

- The location permits fast infiltration and percolation of water

- In a more ideal situation, it is in the valley of the surface layout

The infiltration offered by the selected location further depends upon:

- The depth of groundwater – the lower the better

- Soil surface

- Underlying soil type – offering high percolation rate

The groundwater recharge by constructing recharge pit is best practice to be followed in alluvial areas where there are exposed permeable rocks on the land surface or at the shallow depth.

Construction of Recharge Pit

Recharge pit can be constructed with any shape and size. Its size should remain proportional to rainwater catchment area, but the ideal size is considered to be 1-2 meters wide and 2-3 meters deep. The percolation rate of the soil also contributes towards the size of the recharge pit.

The excavation of the identified site is continued till a layer of porous soil or weathered rock or fracture is reached.

Backfilling

The excavated recharge pit once dug, is ready to be filled with jelly and sand. Jellies of different sizes are arranged at the bottom of the pit, which forms a large gap to allow water to pass through them. The smaller sized jellies are put on the top so that they could support the top layer of sand. A mesh between the layer of sand (for covering the top of the pit) and small-sized jellies is helpful in preventing the sand from escaping at the bottom of the pit.

The leaves, planted earth or a layer of soil can also be used for covering the top of the pit. They are equally able to filter the water.

It was observed that the rate of recharge increases as the side slope of the pit is increased.

Maintenance of the Recharge Pit

To ensure the recharge pit continues to perform its function, proper monitoring must be performed, and timely cleaning should be scheduled.

- The unfiltered runoff water deposits a thin film of sediments on the walls and bottom of the pit. Clean the pit for such deposition.

- The recharge pit can be backfilled with boulders (5-20 cm) at the bottom, gravels (5-10mm) in between and coarse sand (1.5- 2mm) in graded form at the top. The coarse sand layer helps in absorbing the silt that comes with runoff water, thus preventing its further deposition.

- Install a mesh at the rooftop catchment area to prevent debris and other solid wastes from going into the pit.

- The top layer of the sand must be cleaned periodically, for having a maintained rate of recharge.

- Ensure that the catchment area and the runoff water is free from biological and chemical pollutants.

An experiment

In an experiment, a recharge pit with dimensions 1.7 m x 1.7 m x 0.75 m was constructed at Dabhu in Central Mehsana area. The purpose of this construction was to study the feasibility of recharging the shallow aquifers.

For this experiment, the Canal water was used, and the recharge pit was covered to prevent dust deposition and evaporation losses.

The recharge was kept settled and undisturbed for 60 days. During this recharge phase of 60 days, it was observed that the recharge was affected at the rate of 17.3 cubic meters per day with an infiltration of 0.5 m/day. This showed an increase of 4.13m in water level, at a distance of 5m from the recharge pit.

Recharge Pit Gravels and other RWH products at Chaitanya

Excavating the recharge pits is a great idea to help in recharging the depleted levels of groundwater. In case you want to be a part of this cause, Chaitanya Rainwater Products & Systems Pvt. Ltd. has everything concerning rainwater harvesting systems and the recharge structures. The assorted gravels required for backfilling the recharge pits are available in the sizes of 5mm to 10mm.

For rooftop catchment areas, our company has to offer effective and innovative solutions. The rooftop filters are designed to support 0% wastage of rainwater.

Are you confused about the installing a rainwater harvesting system? We can also help in this domain. Our expert engineers have years of experience with conducting hydrogeological and borewell survey and providing with feasibility report with detailed engineering designs and RWH layout.

What more information on Chita ya products